NEWS & EVENTS

- Home

- News

- Products Information

- Taical pellets for injection molding – An optimal solution for the plastics industry

Taical pellets for injection molding – An optimal solution for the plastics industry

November 14,2025

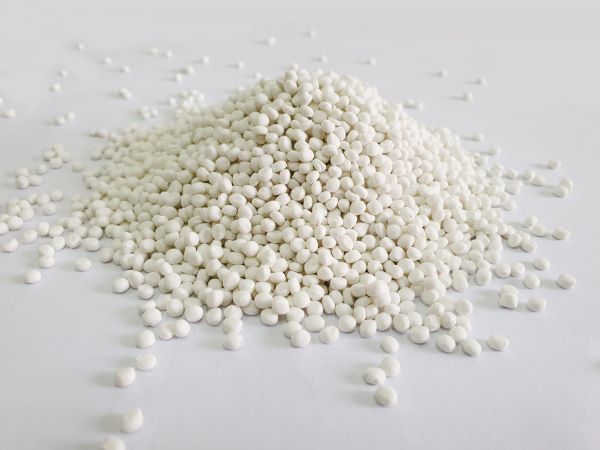

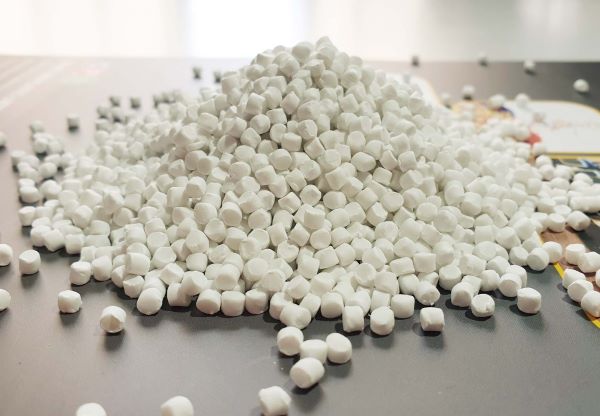

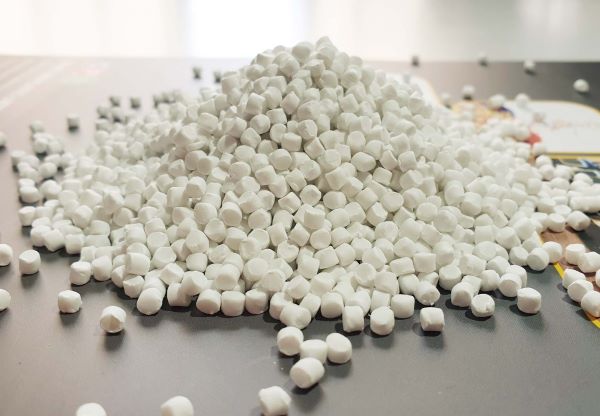

Taical pellets used for injection molding are among the most widely used plastic additives, applied extensively in the production of household plastic products, packaging, and technical components. With the ability to enhance stiffness, increase durability, and reduce material costs, Taical pellets help businesses optimize production efficiency while maintaining high product quality.

Taical pellets used for injection molding are one of the common plastic additives

How Taical pellets function in injection molding

By reducing the amount of virgin plastic, businesses can achieve significant material cost savings. Virgin plastics are generally more expensive than CaCO₃ powder, so partially replacing them with Taical filler pellets provides clear economic benefits. Material cost savings can reach 15–30%, depending on the blending ratio and the type of product.

Common applications of Talc pellets in injection molding

Taical pellets used for injection molding are one of the common plastic additives

How Taical pellets work in injection molding

Taical pellets used for injection molding play a crucial role in improving efficiency and reducing costs in the plastic production process. Their mechanism of action is not merely as a “filler” but also has a profound impact on both the material properties and the processing workflow.

How Taical pellets function in injection molding

Partially replace virgin plastic

During the injection molding process, Taical pellets used for injection molding are blended with virgin plastics (such as PP, PE) at a ratio of 10–40%. This reduces the amount of pure plastic required while still maintaining the mechanical properties of the final product. The ultra-fine CaCO₃ powder in Taical pellets disperses evenly, forming a supporting network within the polymer matrix.By reducing the amount of virgin plastic, businesses can achieve significant material cost savings. Virgin plastics are generally more expensive than CaCO₃ powder, so partially replacing them with Taical filler pellets provides clear economic benefits. Material cost savings can reach 15–30%, depending on the blending ratio and the type of product.

Enhance material properties

Taical pellets for PP injection molding not only help reduce costs but also improve several important mechanical properties of plastic products.- Mechanical enhancement: Taical pellets help increase stiffness (modulus of elasticity), flexural strength, and impact resistance to a certain extent. More importantly, they improve dimensional stability, reduce post-molding shrinkage (warpage), and prevent product deformation during cooling. The presence of Taical pellets creates cooling centers, enabling the plastic to crystallize more quickly and uniformly.

- Surface effects: Products containing Taical pellets often have a glossier, more uniform surface and better scratch resistance. This is particularly important for products requiring high aesthetics and surface durability, such as household items or automotive components. The CaCO₃ powder in the plastic also enhances surface printability.

Optimize the production process

The use of Taical pellets for injection molding not only affects costs and product properties but also contributes to optimizing the entire injection molding process.- Reduced molding cycle time: Thanks to the good thermal conductivity of CaCO₃ powder, the cooling process in the mold occurs faster. This significantly shortens the injection molding cycle time, thereby increasing production efficiency and reducing energy costs.

- Stable plastic flow: Taical pellets help the plastic flow more evenly in the mold, improving the rheological behavior of the polymer blend. This minimizes common defects such as voids, warpage, surface cracks, and other imperfections, especially when producing products with complex shapes or thin walls.

Common applications of Taical pellets in injection molding

Taical pellets, a hydrated magnesium silicate mineral, are widely used as a filler for PP injection molding and other plastics due to their ability to significantly improve various material properties.

Common applications of Talc pellets in injection molding

In household items

Taical pellets are widely used in the production of household items to enhance stiffness, heat resistance, and improve product surfaces.

PP injection molding fillers using Taical pellets are highly effective in producing trays and packaging materials that require strength and stability.

In the production of plastic pipes and fittings

Taical pellets are a popular choice for improving the performance of plastic pipes and fittings, especially pressure-resistant pipes.

In plastic construction and interior materials

Taical pellets are also widely used in the construction and interior industries to produce durable, attractive, and highly stable plastic products.

PP Taical pellets for injection-molded products made from Polypropylene

Taical pellets are widely used in the production of household items to enhance stiffness, heat resistance, and improve product surfaces.

- Products: Spoons, cups, food containers, kitchen utensils, electronic device housings, plastic chairs, plastic tables.

- Benefits:

- Increased stiffness: Helps products better withstand impacts and resist deformation during daily use.

- Heat resistance: Products like food containers can tolerate higher temperatures when placed in microwaves or washed with hot water without deforming.

- Surface quality: Products have smoother surfaces, are more scratch-resistant, and offer a more premium feel.

PP injection molding fillers using Taical pellets are highly effective in producing trays and packaging materials that require strength and stability.

- Products: Industrial plastic trays, component containers, thermoformed packaging, storage bins.

- Benefits:

- High strength: Helps plastic trays be sturdier and less prone to deformation or breakage during transport and storage.

- Dimensional stability: Ensures trays have uniform dimensions, are easy to stack, and compatible with automated systems.

- Weight reduction: Compared to using only virgin plastic, Taical pellets help reduce the overall weight of the product while maintaining necessary strength.

In the production of plastic pipes and fittings

Taical pellets are a popular choice for improving the performance of plastic pipes and fittings, especially pressure-resistant pipes.

- Products: PVC pipes, PP-R pipes, PE pipes, pipe fittings, electrical cable housings.

- Benefits:

- Increased tensile strength and impact resistance: Helps pipes and fittings be more durable under mechanical stresses.

- Wall stability: Prevents warping and deformation during production and use.

- Reduced cracking: Enhances material toughness, lowering the risk of cracking under pressure or temperature changes.

In plastic construction and interior materials

Taical pellets are also widely used in the construction and interior industries to produce durable, attractive, and highly stable plastic products.

- Products: Plastic ceiling panels, plastic door frames, plastic flooring, plastic profile strips.

- Benefits:

- Increased stiffness: Helps products have a solid structure and better withstand applied forces.

- Reduced shrinkage: Ensures panels and frames maintain their original dimensions, avoiding installation and aesthetic issues.

- Improved surface flatness: Produces products with smooth surfaces, easy to clean, and enhances visual appeal.

Types of Taical pellets suitable for injection molding

To optimize the efficiency of using Taical pellets for injection molding, selecting the type of pellet that matches the base plastic and product requirements is extremely important. Currently, there are many types of Taical pellets specifically designed for each application.PP Taical pellets

PP Taical pellets are a leading solution for injection-molded products made from Polypropylene (PP). This PP filler masterbatch is developed to be fully compatible with PP, delivering the highest efficiency.

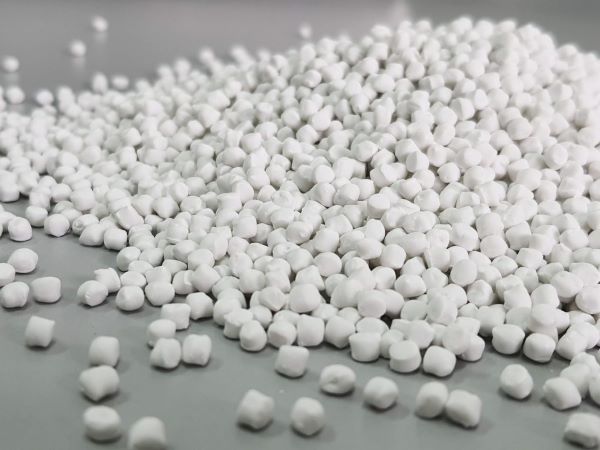

PP Taical pellets for injection-molded products made from Polypropylene

Features: Manufactured on a PP base combined with ultra-fine CaCO₃ powder. This gives PP Taical pellets high dispersion in the PP matrix, ensuring uniformity and stability for the products. They are usually milky white or off-white, in small pellet form, making them easy to blend.

Advantages:

PE Taical pellets for products made from Polyethylene (PE)

Advantages:

- Increased stiffness and heat resistance: Makes PP products sturdier and less prone to deformation under heat or mechanical stress.

- Reduced shrinkage and product deformation: CaCO₃ filler for PP injection molding helps control the shrinkage of PP during cooling, improving dimensional stability of the finished product.

- Lower material costs: A clear economic benefit, reducing the amount of virgin PP required by 10–20% while maintaining or enhancing desired properties.

- Improved molding cycle: Thanks to the thermal conductivity of CaCO₃, cooling occurs faster, shortening the molding cycle and increasing productivity.

PE Taical pellets

For products made from Polyethylene (PE), PE Taical pellets are the optimal choice to improve performance and reduce costs.

PE Taical pellets for products made from Polyethylene (PE)

Features: A type of filler pellet blended from a PE base resin (usually LLDPE, LDPE, HDPE) and ultra-fine CaCO₃ powder.

Applications:

Taical pellets used for injection molding not only help improve the mechanical properties and aesthetics of plastic products but also provide clear economic benefits for manufacturing businesses. Choosing the right type of Taical pellet for each plastic grade contributes to enhancing quality, durability, and optimizing costs in modern injection molding processes. Contact APEX Vietnam now for advice on high-quality Taical pellets used for injection molding, suitable for all production needs!

Applications:

- Production of plastic bags, PE films, and flexible packaging.

- Household items, trays, caps, and plastic parts requiring flexibility and a smooth surface.

- Increased stiffness and surface opacity: Although PE is generally softer than PP, adding PE Taical still enhances stiffness and produces a more opaque, uniform surface.

- Controls shrinkage during cooling: Similar to PP Taical, PE Taical also contributes to maintaining dimensional stability of the product.

- Reduced material costs: Reduces the amount of virgin PE, providing significant economic benefits without affecting processability.

- Improved surface printability: Enhances ink adhesion, making it easier to print logos and information on product surfaces.

| Criteria | PP Taical Pellets | PE Taical Pellets |

| Base resin | PP (Polypropylene) | PE (Polyethylene) |

| Stiffness | Very good, enhances stiffness of PP | Good, increases stiffness of softer PE |

| Flexibility | Less flexible than PE, suitable for rigid products | Very good, suitable for flexible or thin products |

| Heat resistance | Higher, suitable for high-temperature products | Lower than PP, suitable for standard products |

| Main applications | Household items, housings, components, rigid trays | Films, bags, flexible trays, bottles, caps |

Taical pellets used for injection molding not only help improve the mechanical properties and aesthetics of plastic products but also provide clear economic benefits for manufacturing businesses. Choosing the right type of Taical pellet for each plastic grade contributes to enhancing quality, durability, and optimizing costs in modern injection molding processes. Contact APEX Vietnam now for advice on high-quality Taical pellets used for injection molding, suitable for all production needs!